ASI Sniper (Gamo Expo) .177 Project

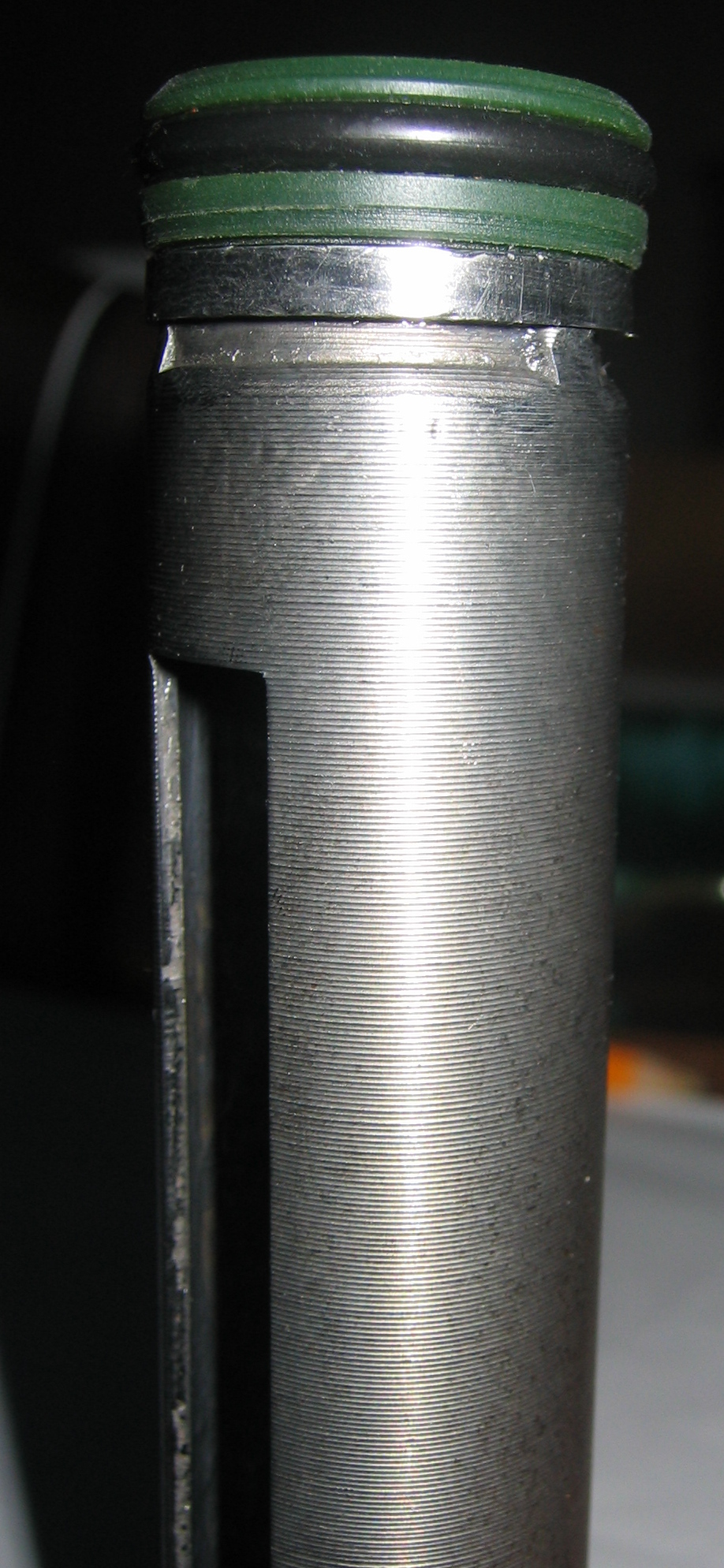

The 'O' ring piston seal conversion we made for my old ASI Sniper ( a re-badged Gamo Expo) .177 to replace the original leather seal - Only the second item my son and I have ever made on a metal lathe (Myford ML7) but it came out really well.

Gave an immediate performance increase but also made the rifle far more consistent with only a 7fps variance over a 10 shot string.

The size of the 'O' ring groove is critical to get just the right amount of "squash" so that the 'O' ring seals but doesn't create excessive friction

(The piston/seal/etc/ needs to be sized specifically to each individual rifle)

Rifle compression tube diameter nominal 25mm

Aluminium stock 25.4mm diameter

Aluminium/Oilon Piston Head machined down to 24.7mm diameter

Piston 'O' ring groove diameter 19.6mm

Piston 'O' ring groove width 3.24mm diameter

'O' ring 19mm I.D. x 3mm Cross section

Next job on the list is to replace the extremely tired original spring with a No. 7 Titan XS spring and add a top hat and ptfe piston sleeve.

MKI - Aluminium O Ring Conversion

MKII Oilon oil filled nylon O ring conversion

ASI Sniper improvements so far:

1. Original condition as received leather seal, tired spring, unknown last lube

2. Stripped, cleaned and relubed - Leather seal oil soaked (seal actually in remarkably good condition)

3. Added Power Washers/spacer to aid tired spring

4. Changed Leather Seal to MKI Aluminium 'O' Ring Conversion - This also increased the stroke a couple of mm as the 'O' ring is more compact than the original seal. Some evidence of scoring on the soft aluminium.

5. Fitted new Spring

6. Fitted MKII Oilon Oil filled nylon 'O' ring conversion - reduced weight for faster lock time and reduced recoil, self lubricating bearing (should eliminate scoring and the friction resulting), made shorter which added yet another couple millimetres to the stroke/swept volume which may help increase power. The flexibility of the nylon may have an advantage here over the rigidity of the original aluminium 'O' ring piston we made first given the suspicion that the compression tube may not be perfectly circular (see comments below). The nylon may also reduce impact shock at the end of the stroke.

7. Made and fitted small Oilon top hat to support lower spring and allow rotation (pending)

8. Can anything be done to improve the trigger (pending, but seems unlikely without major engineering)?

The main limitation to any further increase in performance of this rifle is the trigger. It is a very simple direct single stage trigger which has a lot of pressure on it from the spring/cocking mechanism so it is impossible to get a really light feeling release. The adjustment screw basically just moves the trigger closer to the release point, in fact right to the point when it will, rather dangerously, actually go off when closing the barrel after cocking the rifle if you over do it. I also have suspicions that the bore of the compression tube may be slightly ovaloid rather than perfectly circular which may affect efficiency (the original leather seal may even have an advantage here as it deforms to fill any shape). Having said that at 10 metres it does actually produce a pretty good group although not in the one hole class of my Air Arms TX200 HC. Unless I can find a way of modifying/replacing the trigger unit I don't feel inclined to spend any more time trying to tune it as it is probably not far from as good as it will get now and much better than before I started. Bearing in mind the unsophisticated triggger mechanism Increasing spring strength is only likely to increase trigger pressure even more which is unlikely to help accuracy.

The rifle is currently on (seemingly extended as it hasn't yet been returned) loan to a friend so I can't take final chrono readings. The ASI Sniper probably has more value as a collectors item rather than as a precision instrument and is a little low on power even for short range pest control so more appropriate just for short range target plinking.

| Condition | High ft/lb | Low ft/lb | Avg ft/lb | Spread fps |

| 1 Original as received | 3.19 | 2.22 | 2.7 | 69 |

| 2 Cleaned/Deburred/Relubed | 4.20 | 4.04 | 4.13 | 21 |

| 3 Added Power Washers | 4.69 | 4.37 | 4.51 | 18 |

| 4 'O' Ring Conversion | 5.13 | 5.01 | 5.04 | 7 |

| 5 'O' Ring + New Spring/Top Hat |

? | ? | ? | ? |

Please Note:

I have had a number of enquiries asking me if I can supply 'O' Ring conversions for people. I am afraid I only make these for my own use and amusement and have no wish to make them commercially. To do it properly you really need to size it exactly, with some testing and trial fitting during manufacture, to each individual rifle and spring plus I wouldn't like to make one for anyone else when I have no idea of the life span of the parts etc. If you want to make your own then, if you don't have your own lathe, I suggest that you contact a local model engineering club or one of the more well known rifle tuners and ask if anyone there can help. For an experienced (model) engineer it would be a fairly easy thing to make (my measurements detailed above may help as a starting point).